Aerospace & Defence

01

Coating

Aerospace paints and coatings used in construction and maintenance must be extremely tough and durable, given the conditions in which they operate such as extreme temperatures or a high level of ultraviolet (UV) exposure over their lifetime. Coatings must also be resistant to the chemicals found in jet fuel, or other substances that aircraft frequently come into contact with. Coatings with a blend of solvents are used to achieve optimum solvency and regulate the drying time (for instance n-butyl acetate-based). The coating protects the plane from corrosion to ensure safety and make it last longer.

02

Deicing

If temperatures are below zero, the plane might need to be de-iced before taking off. Alcohols or glycol-based de-icers are ideal for the removal of snow, ice and frost from the wings and frame of the aircraft. They also stick to the surface to postpone the reformation of ice for a limited period.

03

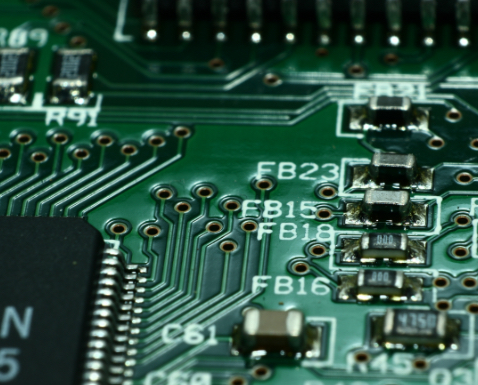

Microchips

Micro-electronic elements are used in the technologies to navigate modern planes. Electronic-grade solvents (alcohols, esters and ketones) with very low levels of metal ions in the solvents are also used to produce microchips. Metal ions can cause short circuits that result in poor-quality microchips. Electronic-grade solvents are used to dissolve a photo-sensitive polymer that is then spun on a silicon wafer to produce the micro-circuit. Solvents are also required to clean the surface of wafers and circuits.

04

Fuel additives

Solvent-based additives (alcohols, ketones or lighter but aromatic hydrocarbon solvents) lower the flash points and enable the fuel to ignite faster and burn longer.

05

Tyres

When aircraft moves on the runway, its body gets charged due to air friction. This charge can cause sparking. Thus to ground, these charge aircraft tyres are made of conducting rubber. Solvents help to make tyres stronger. Dearomatised aliphatic hydrocarbons with specific boiling point ranges are used to produce tyres. The solvent softens and cleans each rubber layer before the next layer is applied. Its adhesive properties help bind together the various components of the tyre, increasing safety and performance. Solvent-based adhesives keep the many different layers of material glued firmly together.

06

Carbon-fibre-reinforced polymers (CFRP)

Ketones such as acetone, MEK (Methyl ethyl ketone) and MIBK (Methyl isobutyl ketone) are used in Carbon-fibre-reinforced polymers (CFRP), which are extremely strong and light fibre-reinforced plastics that contain carbon fibres. CFPR can be used in body panels for cars or in wing spars and fuselage components of aircraft, increasing the high strength-to-weight ratio. The carbon fibres are layered with epoxy resins, and the ketone’s high solvency power softens the resin to apply it easily and evenly between the layers. The solvent’s low boiling point allows it to evaporate quickly, enabling the layers to bind easily and form a robust and durable product.